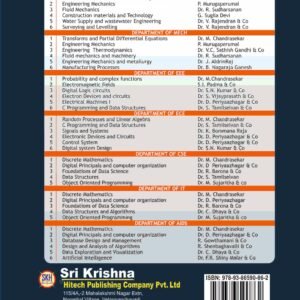

UNIT I : CONSTITUTION ALLOYS AND PHASE DIAGRAMS

Constitution of alloys — Solid solutions, substitutional and interstitial — phase diagrams, Isomorphous, eutectic, eutectoid, peritectic, and peritectoid reactions, Iron — carbon equilibrium diagram. Classification of steel and cast Iron microstructure, properties and application.

UNIT II : HEAT TREATMENT

Definition — Full annealing, stress relief, recrystallisation and spheroidising — normalising, hardening and Tempering of steel. Isothermal transformation diagrams — cooling curves superimposed on I.T. diagram CCR — Hardenability, Jominy end quench test — Austempering, martempering — case hardening, carburizing, Nitriding, cyaniding, carbonitriding — Flame and Induction hardening — Vacuum and Plasma hardening. .

UNIT III : FERROUS AND NON-FERROUS METALS

Effect of alloying additions on steel- a and ß stabilisers– stainless and tool steels — HSLA, Maraging steels — Cast Iron — Grey, white, malleable, spheroidal — alloy cast irons, Copper and copper alloys — Brass, Bronze and Cupronickel — Aluminium and Al-Cu — precipitation strengthening treatment — Bearing alloys, Mg-alloys, Ni-based super alloys and Titanium alloys.

UNIT IV : NON-METALLIC MATERIALS

Polymers — types of polymer, commodity and engineering polymers — Properties and applications of various thermosetting and thermoplastic polymers (PP, PS, PVC, PMMA, PET,PC, PA, ABS, PI, PAI, PPO, PPS, PEEK, PTFE, Polymers — Urea and Phenol formaldehydes)- Engineering Ceramics — Properties and applications of Al2O3, SiC, Si3N4, PSZ and SIALON –Composites-Classifications- Metal Matrix and FRP — Applications of Composites.

UNIT V : MECHANICAL PROPERTIES AND DEFORMATION MECHANISMS

Mechanisms of plastic deformation, slip and twinning — Types of fracture — Testing of materials under tension, compression and shear loads — Hardness tests (Brinell, Vickers and Rockwell), hardness tests, Impact test lzod and charpy, fatigue and creep failure mechanisms.

Reviews

There are no reviews yet.