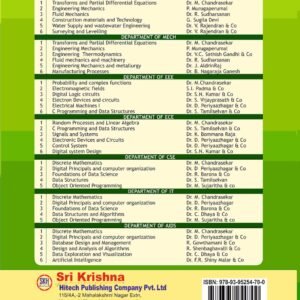

1020236244

PROCESS AUTOMATION

PRACTICUM 1043

THEORY Hrs

Unit – I: HYDRAULICS AND PNEUMATIC SYSTEMS

Pneumatic systems: Elements – FRL unit – Direction control valves – Flow

control valves – ISO symbols of pneumatic components – Pneumatic circuits for

various industrial applications.

Hydraulic systems: Elements – Comparison of pneumatic systems – Service

properties of hydraulic fluids – ISO symbols of hydraulic components – Hydraulic

circuits for various industrial applications.

Unit – II: LOGIC GATES AND PLC

PLC: Features of PLC – PLC Block diagram – PLC scan – Fixed and Modular

PLC – Ladder logic – Basic principles of ladder diagram – Analog I/O and Digital

I/O, NO, NC contacts – Coils – AND logic, OR logic – Applications – Timer –

Counter.

PRACTICAL EXERCISES

Ex.No Name of Experiment Hrs.

1. PNEUMATICS LAB

Operation of double acting cylinder with quick exhaust valve.

15 2. Speed control of a double acting cylinder using metering-in and

metering-out circuits.

3. Automatic operation of double acting cylinder in single cycle -using

limit switch.

4. HYDRAULICS LAB

Direct operation of double acting cylinder.

10

5. Speed control of double acting cylinder using metering-in and

metering-out circuits.

6. PLC LAB

Direct operation of a motor using a latching circuit, AND, OR logic

circuits. 25

7. On-Delay control of a motor and Off-Delay control of a motor.

(ii)

8. Automatic operation of double acting cylinder Multi-cycle

9. Sequential operation of a double acting cylinder and a motor.

10. Automatic operation of DAC, forward – time delay – return.

Assessment Test and Revision 10

TOTAL HOURS 75

Reviews

There are no reviews yet.