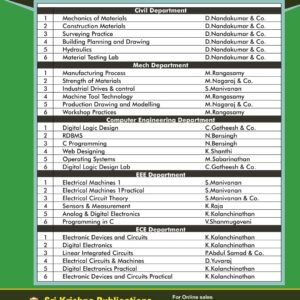

1020234640 METROLOGY AND MEASUREMENTS

PRACTICUM

Syllabus contents

THEORY

UNIT I: LINEAR MEASUREMENTS AND COMPARATORS Periods

Basics of Metrology

Scope of Metrology, basic units, important terminology, Measurement – Need,

Process, Role in quality control; Factors affecting measurement – SWIPE;

international standardization, the bureau of Indian standards – important elements

of measurements – methods of measurements.

Precision – accuracy – definition – factors affecting the accuracy of the measuring

system – general rules for accurate measurements – precautions for use of

instruments so as to avoid in accuracy in measurements – reliability – definition,

Measurement uncertainty, Measurement system analysis, Compare systematic

error and random error, Selection of measuring instruments – Calibration of

measuring instruments.

Linear Measurements

Linear Measuring Instruments – Vernier caliper, Micrometer, Vernier height gauge,

Depth Micrometer, bore gauge, Telescoping gauge; Gauge blocks – Use and

precautions, possible sources of errors in micrometers – slip gauges –

requirements – Indian standard – care and use.

Comparator

Comparators – Working and advantages – Types – Mechanical and Pneumatic

Comparators.

Practical Exercises:

Ex. No Name of the Experiment Hours

1 VERNIER CALIPER

i) Measure the dimensions of ground MS flat/Cylindrical bush using

Vernier Caliper.

ii) Compare the results with Digital Vernier Caliper.

2 OUTSIDE MICROMETER

i) Measure the diameter of a wire using micrometer

ii) Compare the results with a digital Outside micrometer.

3 INSIDE MICROMETER

i) Measure the inside diameter of the bore of a bush cylindrical

component using Inside micrometer

ii) Compare the results with digital inside micrometer.

4 SLIP GAUGES

Measure the thickness of ground MS plates using slip gauges.

5 VERNIER HEIGHT GAUGE

Measure the height of gauge blocks or parallel bars using vernier height

gauge.

6 MECHANICAL COMPARATOR

Find out the measurement of a given component and Compare with a

standard component using a mechanical comparator and slip gauge.

THEORY

UNIT II: ANGULAR MEASUREMENTS, CMM, SURFACE & ADVANCED METROLOGY

Angular Measurements: Angular measuring instruments – Bevel protractor, Angle

gauges, Precision level, Sine bar, Autocollimator. Opto-mechanical measurements

using a measuring microscope and Profile projector. Measurement of Screw threads

– Single element measurements – Pitch Diameter, Lead, Pitch. Measurement of

Gears – purpose – Analytical measurement – Runout, Pitch variation, Tooth profile,

Tooth thickness, Lead.

Coordinating measuring Machine: Basic concept of CMM – Types of CMM –

Constructional features – Probes – Accessories – Software – Applications.

Advanced Metrology: Basic concepts of lasers – types of lasers – laser and LED

based distance measuring instruments.

Ex. No. Name of the Experiment

7 UNIVERSAL BEVEL PROTRACTOR

Measure the angle of a V-block/Taper Shank of Drill/ Dovetail using

universal bevel protractor.

8 SINE BAR

Measure the angle of the machined surface using sine bar with slip

gauges.

9 SCREW THREAD MICROMETER

Measure the geometrical dimensions of V-Thread using screw thread

micrometer.

10 GEAR TOOTH VERNIER CALIPER

Measure the geometrical dimensions of spur gear using gear tooth

vernier caliper.

Reviews

There are no reviews yet.